Metal Injection Molding

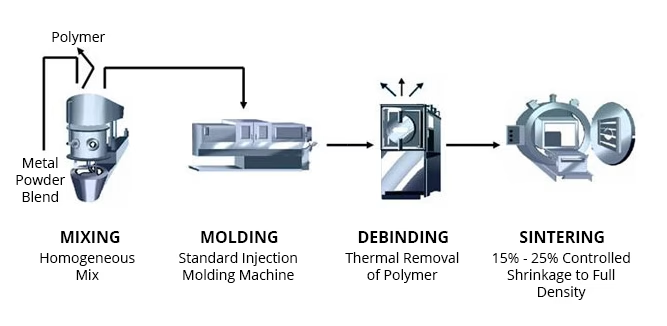

Metal injection molding (MIM) is a hybrid technology which integrates the shaping capability of plastic injection molding and materials flexibility of conventional powder metallurgy. MIM is preferred for mass manufacturing of small, intricate geometric components of a variety of materials as it can achieve 95% to 98% of its wrought materials properties at a much lower cost.

Technology

The initial step to MIM is material selection and preparation. Once the appropriate combinations of metal powder and plastic binders are blended and compounded, an injection moldable feedstock is produced.

Using an injection-molding machine, the parts produced are then subjected to a binder removal process. Depending upon the type of binder used, different methods of debinding are applied.

The parts, after debinding, then go through a sintering process to ensure the parts are of the right material composition, physical properties and correct geometry.

Process Overview

Advantages

Greater design freedom

With MIM, parts can be designed and manufactured with minimal design restrictions. In addition, almost all design changes are possible within the shortest development cycle and turnaround time.

Complex and intricate shaped parts

MIM is ideal for producing complex-shaped components as well as parts that require assembly or multiple steps to put together.

High production requirements

MIM is most beneficial in high volume production of small precision parts with complicated design geometry. The process lends itself to automation where high volumes and consistent quality are required.

Miniaturization

MIM technology is the best viable process for producing miniature parts economically.

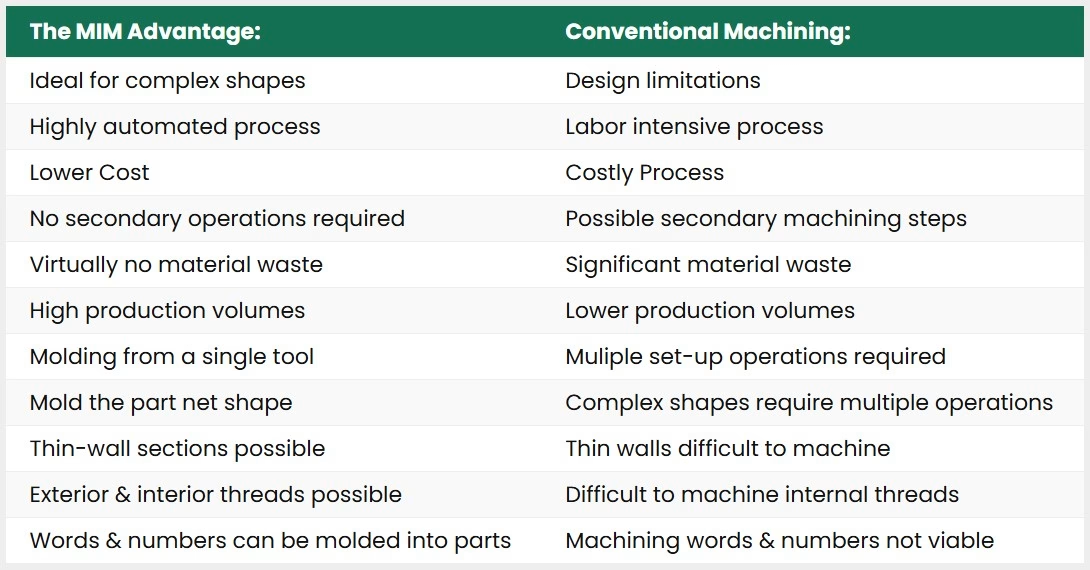

MIM vs. Machining

| The MIM Advantage: | Conventional Machining: |

|---|---|

| Ideal for complex shapes | Design limitations |

| Highly automated process | Labor intensive process |

| Lower Cost | Costly Process |

| No secondary operations required | Possible secondary machining steps |

| Virtually no material waste | Significant material waste |

| High production volumes | Lower production volumes |

| Molding from a single tool | Muliple set-up operations required |

| Mold the part net shape | Complex shapes require multiple operations |

| Thin-wall sections possible | Thin walls difficult to machine |

| Exterior & interior threads possible | Difficult to machine internal threads |

| Words & numbers can be molded into parts | Machining words & numbers not viable |

Applications

MIM technology has found increased applications in the commercial world – from home appliances to watches, automobiles to aerospace, and medical to orthodontics.

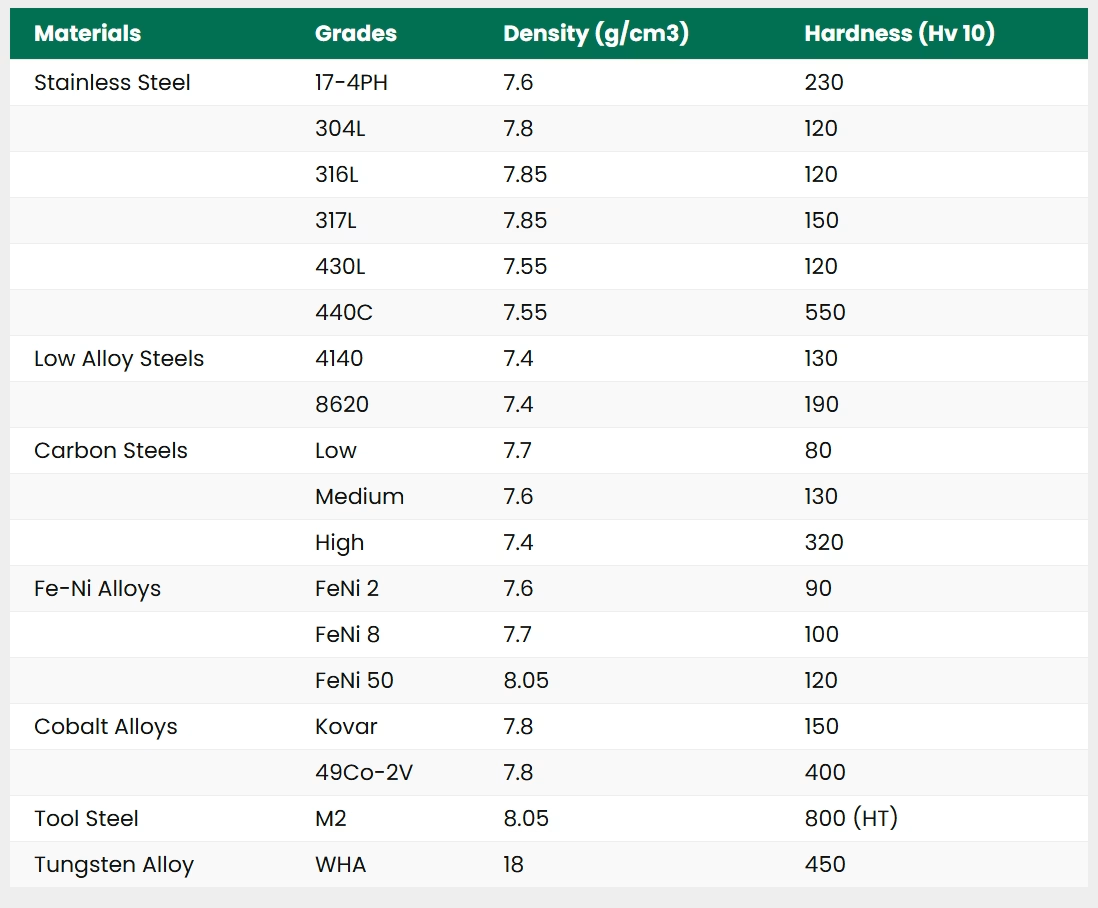

Materials

Due to the flexibility of MIM technology, it is possible to customize material compositions according to the specific attributes required by the customers. Some of the compositions are stainless steels, low alloy steels, carbon steels, Ni-alloys, tool steels and tungsten alloys.

| Materials | Grades | Density (g/cm3) | Hardness (Hv 10) |

|---|---|---|---|

| Stainless Steel | 17-4PH | 7.6 | 230 |

| 304L | 7.8 | 120 | |

| 316L | 7.85 | 120 | |

| 317L | 7.85 | 150 | |

| 430L | 7.55 | 120 | |

| 440C | 7.55 | 550 | |

| Low Alloy Steels | 4140 | 7.4 | 130 |

| 8620 | 7.4 | 190 | |

| Carbon Steels | Low | 7.7 | 80 |

| Medium | 7.6 | 130 | |

| High | 7.4 | 320 | |

| Fe-Ni Alloys | FeNi 2 | 7.6 | 90 |

| FeNi 8 | 7.7 | 100 | |

| FeNi 50 | 8.05 | 120 | |

| Cobalt Alloys | Kovar | 7.8 | 150 |

| 49Co-2V | 7.8 | 400 | |

| Tool Steel | M2 | 8.05 | 800 (HT) |

| Tungsten Alloy | WHA | 18 | 450 |

Check out our other Capabilities & Services

Ready to discuss your Contract Manufacturing Needs?